Groupset

Rear Derailer

The Rival 22 short cage RD comes in at only 179g. That’s only 1g heavier than the Force 22 with a carbon cage. It’s also about half way between Dura-Ace and Ultegra weight, despite being third-tier.

You might be wondering, how is this possible?

First, lets start off with what makes a SRAM rear derailleur different from the rest. Yes, it has 1:1 actuation and that funny looking pulley cam, but there are significant differences in the way a SRAM RD is constructed.

Several bicycle mechanic authorities claim that Shimano invented the modern derailer, which all modern derailers are patterned off of. This isn’t true. A SRAM RD actually has more in common with a Suntour derailer than a Shimano one, because it uses a single sprung pivot design. Modern Shimano, Campy and Microshift road rears have a sprung b-knuckle (copied from Simplex), where the RD attaches to the hanger which helps the derailer adapt to a wider range of cog sizes. A single sprung design on the other hand does not have a spring there, it is essentially rigid in operation, and only moves out of the way when removing the wheel. The path of the jockey wheel is rigidly defined by the parallelogram geometry. It’s also popular in MTB because it helps reduce chain bounce, since the pulley cage isn’t floating. That’s another reason SRAM shares another design feature with some Suntour designs, it features an upper jockey that is concentric with the lower pivot, because otherwise front shifting would change the location of the pulley (and this is why 1x has lots of off-set instead of a slant parallelogram). Other details, such as the the alloy fixing bolt can be found on the Sutour Superbe. The concentric pulley and something similar to the pulley cam can be found on a Suntour Vx GT. All that being said, the Suntour Cyclone is even lighter than the Rival because of a clever cable route and light weight construction.

Basically, it’s simpler and lighter, because they didn’t copy Shimano (they copied Suntour)

SRAM also uses some interesting choices of materials on the Rival RD. It has an alloy inner plate, like what is traditionally found on Ultegra derailers. It also has an alloy fixing bolt, which saves a significant amount of weight over a steel one, although after market ones have had a reputation for cracking and the bolt is softer and easier to strip. This is why Shimano uses steel fixing bolts, or the funny looking 2-material bolt on Dura-Ace. SRAM also uses a plastic lower A-knuckle for the Rival, that’s right, plastic. Shimano did the same on Sora and Acera, and Tourney has both plastic knuckles. While Shimano copied the Simplex dual sprung pivots, they didn’t share Simplex’s affinity for plastic derailers. Plastic is cheap, but it’s also light. For things that won’t require lots of strength, but need to take a certain shape, plastic can be about as light as carbon fiber. SRAM also uses aluminum for the cages, because the truth is, aluminum really doesn’t cost much more than steel. It’s not all weight-saving corner-cutting for SRAM though. SRAM put ball bearings in their jockeys (13g ea), which makes them higher quality than bushings, but with a thick grease and an undemanding job, they don’t necessarily spin better. It does add weight and cost though.

Shimano trickles down technology, but not weight, weight is a key defining factor for product differentiation as well as perceived quality of construction. SRAM is willing to keep the weight weenism going in the lower tiers, and will use use whatever mix of cheap and expensive processes based on how much it can help reduce weight to meet a price point.

And the last bit, why is the Rival 22 RD only 1g heavier than the Force 22 RD, even though the Force 22 RD has a carbon cage? That requires a look at Force 10. It’s basically the exact same thing as the Force 22. Same weight, same construction, same design, different color. Moving over to the Rival side, Rival 10 was 188g, 10g heavier than Force because of the metal cage. However, unlike Force, Rival 22 was redesigned, with a new front plate, and possibly other changes, reducing weight by 9g. It’s very likely a Rival 22 RD with a Force cage would be ~10g lighter than a Force 22. However, because Rival 22 is only 1g heavier, they had to cripple it, by intentionally painting it with ugly glitter silver paint (like older Sora) even though the shifters use white paint.

So, Rival 22 RD is quite competitive with Force 22 because it got a revamp coming from 10 speeds, unlike Force.

Front derailer

The yaw FD is a nice piece of kit, it yaws and stuff, you can read about it in the marketing material. It can be finicky to set up. It works by having some not so parallel pivots in their parallelogram. To prevent binding one of them slides.

Anyways, it’s 76g without the bolt (79g with bolt, SRAM catcher is 10g without mounting bolt, not used here)

It’s also exactly the same as the Force 22 unit. They are identical, except for the paint and labeling. Rival is black. Force has flashy graphics and $15 more expensive. Mechanically, they are the same, weight-wise they are identical. Both are 79g +10g for the catcher. I couldn’t tell you the actual weight of the RED unit. It’s not clear to me if they changed RED production at some point in time. Early versions have actual weights of 77-78g, within a couple grams of Rival. SRAM used to list RED as 74g without chain catcher, although now they say it is 69g. So a Rival FD is only 1-10g heavier than a RED and identical to Force.

Although some renderings show Force with a matte plated cage, actual units seem to be bright chrome just like the Rival. It also features some plastic at the tail of the cage to keep the front and back together, and replaces some steel and a rivet or a screw that would normally be there. Unlike Shimano who has such high production numbers that they can make new tooling for different groupsets, Campagnolo and SRAM will often share parts or sub-assemblies in their components with minor graphic changes and a few small-parts substituted for others.

So for the RD and FD, despite being “third-tier” there’s basically no weight penalty (0.2g listed) compared to Force.

Shifters

The shifters are a whopping 5g over list (+1.5%) at 337g instead of 332g. That being said, they’re still very light. There’s only about a 25g penalty compared to Force (carbon levers), and substantially lighter than Dura-Ace, and still lighter than Super Record. SRAM makes the lightest shifters. I’m not the biggest fan of double-tap, but it is clever. It saves weight. It works.

I suspect that Ultra-Shift actually weighs more than Power-Shift, as the escapement mechanism in Power-Shift is simpler. Power shift, in addition to having a separate thumb lever, needs separate engagement mechanisms for both shift levers so they don’t interfere with each other (push one lever in, then other other so they’re engaged at the same time, and you can see what I mean), and SRAM doesn’t have the thumb button, and it doesn’t need an engagement mechanism, because there’s no thumb button trying to turn the pulley the other direction. I suspect a ratchet and escapement mechanism is also lighter than the sprung detent system used by Power-Shift. Athena Power-Shift of course is crippled by needing to be heavier and inferior. If Campy can’t have any real product differentiation between SR, Record and Chorus, they can at least do so for Athena and Centaur.

Shimano only has 2 levers, just like SRAM, a brake lever and a shift lever. But Shimano needs a heavy duty gimbal that can withstand braking forces, and with the advent of hidden shift cables, it also needs a gimbal mechanism that keeps the brake and shift inputs separate and transfers them to the shifter body. It also needs to transfer the input from the dedicated shift lever. Shimano’s control system really wasn’t designed to house the shift internals in the shifter body, but on the lever itself. The mechanism to get all the lever inputs into the body of the shifter is not uncomplicated. SRAM’s gimbal is simple, it only needs to take low forces (and some of them still snapped) and it only has to keep and pass on a single input to the shift internals. Again, it also doesn’t need a second lever for the escapement.

SRAM’s exact actuation technology, which means the cable pull is identical when shifting from the first cog, and shifting to the eleventh cog, means the escapement ratchet is simpler too, the same teeth are used by the escapement, rather than requiring a separate set of teeth to time both sides of the escapement to each other. However, there’s some drawbacks, most annoying is the behavior in the 11th cog. If you try to downshift to the 12th, the lever gives a very unpleasant feeling before releasing and not doing anything. This is an improvement over earlier models, which simply upshifted, and gave you a harder gear when you wanted an easier one.

So if you were wondering why SRAM levers are so light, that’s why.

179g + 79g + 337g = 595g for the shifting bits, and these are the only parts that strictly have to play nice with each other. That’s only 5g more than the equivalent Dura-Ace parts, and 2g heavier than the equivalent Record parts. So despite no carbon bits in Rival, at least for these 3 parts, it’s still extremely competitive with other top shelf shifting parts.

Cassette

No picture – 256g

Generally most of the weight savings between second and third tier cassettes the lockring, and sometimes the spacers, which can be recycled from an old cassette. The loose cogs are usually identical. The spider may have some very small differences, but not enough to justify buying a 2nd tier cassette twice to me. Shimano is a bit better than SRAM in this regard because they have 2 spidered clusters for Ultegra, which may be worth it if not for the weight, then for the fact they won’t notch alloy freehubs as badly.

As an experiment I compared the spacers and lockring off of a 12t Shimano CS-5800 cassette, and to those of a 11t SRAM PG-1170 cassette.

SRAM alloy:

5g spacers

5g lockring

10g total

Shimano steel/plastic:

10g spacers

14g lockring

24g total

That makes a difference of 14g. I don’t have a PG-1130 on me to compare, but list weight for a 11-28 PG-1130 is 271g, for PG-1170, it’s 257g, a difference of… 14g. To be fair, the SRAM 11t lockring and spacers might be a couple grams lighter. This isn’t really a fair comparison, because it is SRAM with an 11t lockring vs Shimano with a 12t lockring. But pretty much all the weight difference is in the spacers and lockring. There’s almost no difference in the cogs. Meaning if you already have a PG-1170, save the aluminum bits and buy a PG-1130.

True, a smaller cassette would weight less, so would a fancy cassette, but it’s a consumable, full steel cogs lasts longer and cost less, and a lightweight bike should have climbing gears.

Chain

No picture – 241g

It doesn’t make any sense to buy a Force chain over a Rival chain. The weight savings is an entire 3g on a consumable. I wouldn’t pay the price differential even if a chain wasn’t a consumable. PC-1130 is 259g, PC-1170 is 256g. SRAM RED or a KMC SL would be a bit lighter, but I’m not inclined to spend extra money on consumables for very marginal gains in excess of $1/g. I removed 8 links, which is 18g worth of chain. So 241g for the chain. Covered in sticky SRAM grease, so no pictures.

Brakes

There’s a ton of weight savings to be had in brakes, mostly because the big brands don’t want any liability issues for bad braking, and being called unsafe by reviewers would really kill the chances of success of a groupset. Actual weights for the lightest big brand brakes is around 230g for (single pivot) Aero-Links with hardware and without pads. The KCNC CB1 brakes come in at 142g and are dual pivot.

Obviously these come in way below the weight of the big brands, and are pretty much the lightest dual-pivot alloy brakes out there, although the unconventional eeBrakes come pretty close.

The brakes have a number of quirks. The first you might notice is the symmetrical dual-pivot design like current Shimanos, which came out after the KCNC brake. What you might not realize is the design is far older, and dates back to the 60’s with the introduction of Altenburger Synchrons. Lots of people like to credit Shimano with the invention of the dual-pivot brake, because Campy was still using single-pivots when shimano was using dual-pivots (and Campy still makes single-pivot brakes to this day). As advertised by GB who made Synchrons under license, “A side-pull fitting brake with centre-pull brake action.” A very accurate description. They look pretty much like old center-pull Weinmann brakes that were ubiquitous on bike-boom bikes, except modified for side-pull actuation. These were the original dual-pivot side-pulls.

Unfortunately, they were poorly constructed brakes, found only on the trashiest bikes, and people got sick of heavy poorly set-up center-pulls with flexy cable hangers, and the design never really gained steam. Campy didn’t invent the single-pivot side-pull, but they certainly made them lightweight and raceworthy, and soon trends dictated side-pull brakes on racing bikes. Shimano later introduced a hybrid one-and-a-half-pivot side-pull, which is commonly known today as a dual-pivot side-pull, where the left side is like a single-pivot side-pull and the right side is off-set like a center-pull or a Synchron, and it uses a cam to synchronize the arms like a center-pull (Mafac not included) or a Synchron. It provided the self-centering (or rather non-floating) action of a center-pull or a dual-pivot, with the simple compatibility of a side-pull and compromised on weight. This allowed the pads to get closer to the rim for stronger leverage. The Synchron, and the center-pulls didn’t take advantage of the potential for increased leverage though, and were generally just as weak as any other non-dual pivot brake. Note that a single-pivot brake tracks an out of true wheel better and generally provides more tire clearance (to compensate for the lack of a rigid linkage defined action), and dual pivot brakes could only really take off when wheels were reliable enough to stay true. Campy still uses single pivot on the rear of some groupsets to save weight. The modulation marketing thing isn’t really true, that has more to do with leverage ratios.

The CB1 has some other quirks, it is known to be flexy, have low power and friction from the arms rubbing together when they flex. They also feature a barrel adjuster that doesn’t fit high quality brass ferrules. To make up for these shortcomings I used Kool-Stop salmon pads and Odyssey Linear Slic[sic] outers.

Kool-stop salmon pads also trace back their history to the bike-boom era. The compound was created by Mathauser. The secret ingredient was rust (the normal industrial purpose is jewelers’ rouge, a metal polish). Back then, bikes were made from steel, and they used the rusty remains of bikes killed by water and rust, and imbued their vengeful spirits in brake pads to offer superior braking in the wet. Or something. They have a reputation for being grippy. They’re also ugly and red, so they got the sharpie treatment. Technically, I should have used Dura 2’s, which are thicker, which would have helped compensate for a narrow rim, and narrower for thin brake tracks. All of these things would have helped. But I had plain Dura’s on hand, so for the time being, that’s what it gets. 20g for 4, although there is some variation between individual pads.

For the cables, I used Odyssey Linear Slic. They are advertised to “to prevent the cable from binding when the cable is twisted around during barspin or tailwhip tricks” when doing mad BMX tricks. That’s cool, but trying to do that on a road bike means a dented top tube. While BMX might have their own purposes for compressionless brake housing, it also has benefits in improving brake performance. It’s commonly specified and recommended for mechanical disc brakes for this reason. Compressionless housing does not improve power, although it might feel like it. A pound of pull on the cable is a pound of pull on the brakes. What it does is it reduces the lever throw to apply the same force (without changing the leverage ratio, nothing is flexing when the pads aren’t on the rim) by making the system less spongy and springy, and more rigid, giving a snappier feel, more pad clearance, and prevents the brakes from bottoming out as easily. In other words it helps compensate for the flex found in the calipers by making the cables more rigid.

The braking isn’t too bad since they’re used on alloy rims, but the action is not as refined, and barely adaquare when trying to come to a complete stop on a -15% grade.

For the record: I mention their lack of power, and the things required to get them usable in case anyone gets the idea to try and copy parts of this build, because they are not suitable for larger riders, especially not on carbon rims.

Crankset

No picture

Cranks used to be pretty basic things, made out of steel, and attached with tapered cotters adapted from other machinery. Some were fluted like I-beams, but I-beams or channel (U-beams/C-beams) suffer from lack or torsional rigidity, and because the pedal is offset to the side, a crank arm should be torsionally strong and stiff, which limited weight reduction from fluting. You still see the channel design on a lot of modern cranks though, because it is stronger and lighter than a solid crank arm of the same size. The ideal place to remove weight from a crank is the core, the ideal shape, a hollow tube. There were in fact, hollow steel cottered cranks in the 40’s. The design is quite clever, and uses the cotter to cover the hole drilled into the arm, so the hole does not interfere with the spindle interface. However, gun drilling is a relatively expensive and difficult process. These got sidelined as lighter aluminum cotterless cranks (square taper) took over for performance applications pretty much through the bike boom, which is why the fluted design of Campy NR cranks is so classic. Those straight fluted arms have been around in one form or another for a long time.

Following the bike-boom, there was a small renaissance of boutique parts makers in the 90s, churning out all sorts of exotic CNC parts, and several of these companies again saw the crank as a place to innovate, but this time using new materials and construction techniques to again attempt a hollow crank arm design.

With the advent of TIG-welding technology being used on frames, some tried to weld up cranksets made from metal tubes, such as Sweet Wings and Bullseye among others. However, these were prone to failure and when made light weight, skilled labor intensive, making them expensive. You generally only see this design still used with heavy duty BMX cranks, where the high-strength to weight is used to maximize strength rather than reduce weight and the heavy construction makes welding easy and cheap.

However, many of the small shops specialized in CNC, allowing the small scale production of meticulously (or not) engineered parts. Among these designs were the bonded metal cranks, like Magic Motorcycle, in which two carefully hollowed out halves of crank arms were glued together. This allowed for the precise control of thickness and shape along the entire length of the crank arm. Cannondale adopted this technology with their CODA brand of components. These however, were again prone to failure and debonding, and Cannondale had to recall many of them. However, they have presumably gotten better at it, because they still make them, the SiSL is still made in the same way and is among the lightest cranksets.

In the late 90’s Shimano caught on (it would be a while until Campagnolo introduced hollow cranks, or even ventured away from square taper) and created a process to forge hollow cranks, leveraging their large size, high capacity and industrial might. Forging requires extremely expensive tooling and machines, but in many ways creates an optimized design with optimized grain (if not cast). However, it is only cost effective with large mass production. This technique is still used for many forged hollow cranks. Some bicycle mechanic authorities claim that two halves are forged like the CNC bonded designs, but then welded together. I am extremely skeptical of this claim however. My personal experience and research indicates crank arms were either cast or forged with a hollow cavity open on the pedal side. The die or the sand filler is removed, and the pedal side is forged and pinched shut sealing off the hollow cavity and giving a place to drill the pedal eye. However, newer Shimano cranks like FC-9000 and FC-6800 are actually forged in halves, but bonded, not forged together.

Modern carbon designs give no regard to this kind of construction, and because of how carbon is laid up, usually require less ingenious construction. However, no carbon on this bike.

The crank I’m using uses none of those methods to achieve hollow construction. Like those 40’s Duprat steel cottered hollow gun drilled cranks (although I doubt these makers knew it existed), these cranks are also drilled lengthwise through the length of the crank. One of those small CNC boutique companies by the name of Ay Caramba tried their hand at an aluminum version of a gun drilled crank. To prevent interference with the square taper interface and the pedal eye, the holes were offset, and the material between the two bores fluted creating quite the unusual look. However, as I noted before, gun drilling is a relatively difficult process. Their Double Barrel crank was known for a very flashy appearance and light weight, but prone to failure because of the poor quality of the gun drilling, leading to bores that were not straight and had uneven wall thicknesses, which again led to this construction method being sidelined.

Much later, KCNC released a similar design, but with the bores going through the pedal eye, and stopping before the spindle interface, and plugging the ends of the holes with aluminum plugs, which allowed them to tap the pedal eye to accept pedals, resulting in a fairly straight conventional look and a single flute on the front. The Rotor Agilis, like the Duprat long before it, has a single bore coming from the other side as to not interfere with the pedal eye, and used an unusual septagontal taper to compensate for the fact that the spindle interface had a hole in it, requiring only a cosmetic plug instead of a structural plug like the KCNC.

Enter the Rotor 3D(24) and the eeCrank. No, they are not copies of each other. Yes, superficially, they look the same, both have 3 bores, and 2 flutes. Both prototypes were made around the same time. eeCranks came up with a design to optimize weight where all 3 holes were drilled from the spindle side as to not interfere with the pedal eye. The way the spindle way attached to arms, the bores only interfered with the bolt to tighten the arms. The bores were kept clear away from the actual spindle interface by putting the bores next to the interface instead of through it.

Rotor looking to increase stiffness to weight arrived at 3 as the logical conclusion and natural evolution of their Agilis. They took their single bore on the spindle side, and flanked with with bores coming from the pedal eye side which did not interfere with the pedal eye and stopped before interfering with the spindle interface. This allowed the bores to be on the same level as the spindle interface, and accommodated a Shimano style pinch bolt design.

That led to the 3DF and 3D+ designs which use a long BB30. This design is a lot closer to the eeCranks than the 3D24. All 3 bores are from the spindle side and plugged. It’s easier to do all bores from the same side, and it allows you more flexibility on the size of the bores. Since aluminum spindles aren’t particularly accommodating to pinch bolt designs, Rotor uses a tapered splinled interface and a SRAM style BB30 adjuster. From my estimation, it still isn’t like the eeCrank that avoids bore/spindle interference. In developing their power meter, they realized they could just stick everything inside the spindle. Thus the Inpower.

So knowingly or not, Rotor has a design with roots reaching back to the earliest hollow weight weenie cranks.

Rotor BSA30: 96g (list)

SRAM Chainring bolts: 9g

The older version of SRAM 10 speed 48t chainrings with the cut outs weighs in at 89g, the same weight as the 50t. I slightly prefer 48t, and the smaller gap, and much better timed pins makes this shift faster than the 50t. The fact that I’m using a 48t ring is purely out of personal preference, not weight savings. I also have a SRAM 50t ring that is the same 89g.

The SRAM 10 speed 34t ring, which seems to be common to most of their cranks, is actually one of the lighter 34t rings, at 28g, even when compared to some weight weenie options. It’s also one of the cheaper ones.

Even though I’m using 10 speed chainrings, there’s not really a problem. Chainrings getting closer to each other with increasing numbers of speeds is not true, and has not been true for some time. This was true when they moved to 9 speed and then first generation 10 speed, but then there were issues with interference during cross chaining, and the teeth were moved out, but the ramps on the chainrings moved in so the ramps bridge a bigger distance. YAW actually has the teeth spread further than before.

This lithium battery is guaranteed against leakage, will last several times longer than an alkaline, and is 10g lighter.

A tuned Shimano 105 FC-5750 would have actually been a little lighter with a BB-9000 (-15g for alloy CR bolts, -3g for pinch bolts, -24g with the SRAM rings) and kept consumables standard, but obviously would have lacked power, which is where all the weight savings go. Also that would make me mix Shimano with SRAM. An old Rival OCT crank would be a bit heavier. A new Rival 22 crank would be much heavier. Even Apex is lighter. There’s not much to tune either, you’re stuck with a GXP BB for BSA, and SRAM rings are already light and come with alloy chainring bolts. This isn’t an entirely fair comparison though. Rotor’s UBB means on a BSA frame it has a 29g penalty because of the bottom bracket. On a BB30 frame, it would be the Shimano crank suffering a weight penalty due to an adapter. Shimano cranks also don’t have power meters, and the non-power version of Rotor cranks is about 60g lighter. Rotor’s Inpower is more advanced than a simple glue-on unit like a Stages.

Cables

(Updated 6-26-16)

No picture

The cables used were just plain stainless slick inners, Jagwire shift outers, and the aforementioned Linear Slic brake outers, with a couple of frame protectors. Estimated to be around 160g 150g.

Wheels

Wheelset

Custom hand-built (by me) from Bitex RAF10/RAR9 hubs, Kinlin XR-200 rims, CN424 spokes, alloy nipples and Veloplugs, they come out to 1250g for the set. That makes for a very light wheetset, but on the other hand, it’s really not a stiff wheelset.

The RAF10/RAR9 is lighter than the standard Bitex hubs, but at their normal price, not really worth the money, considering they use smaller bearings. Cartridge bearings let small manufacturers produce high quality hubs, because they don’t have to make the bearings and leave that to firms that specialize in only ball bearings. That means a lot more variation from the traditional sizes found in cup and cone hubs, and if you’ve ever rebuilt a cheap cup and cone hub, you’d realize why every small hub maker that doesn’t have the production volume and machinery of Shimano and Campy makes cartridge bearing hubs. Even way back, some boutique hub makers like Maxicar used SKF bearings, although they used an adjustable angular contact bearing, not the kind of cartridge bearings popularized by Phil Wood. Bitex hubs don’t always have the bearings set in perfectly and they have aluminum Shimano freehubs, even though the spline pattern designed for steel, but so do most lightweight hubs. Campy at least realized they could make a spline pattern meant to be aluminum, although with the newer alloy freehub designs with a single steel spline, it’s not so much a problem anymore. The reason why Shimano freehubs are designed for steel is because the old freehubs have bearing races and the pawl ratchet ring machined into the inside of the freehub body. Cartridge bearing freehubs modeled after the Campy freehub don’t. Shimano has outboard hub bearings. Campy’s freehub is more like a better supported freewheel with an outboard bearing that helps prevent axle bending loads.

XR-200s are flexy, and light and flexy. But they’re cheap and light, and work adequately if you aren’t too heavy for them and don’t mind pinned rims.

424 spokes are of mixed quality. They’re definitely not as nice to build with as a brand name spoke, and I completely understand why most wheel builders don’t want to waste their time on them. Threads are not great, and may require some clean-up, but it gets you something similar to a CX-ray at Laser price, and when comparing them to Lasers, at least the fact that they’re bladed helps their buildability compared to the wind-up prone Lasers.

Veloplugs are very light, and an excellent $/g upgrade for non-tubeless clinchers. If they fit. Since they’re made by Velocity for Velocity rims, they don’t fit all rims or may require modification. I used yellows, although apparently not all XR-200 rims are drilled the same.

For the record: I have another stiffer and slightly more aero Kinlin XR-270 wheelset that weighs in ~150g heavier laced to normal Bitex hubs. I note that the XR-200s are flexy in case anyone gets the idea to try and copy parts of this build, because they are not suitable for larger riders, at least not with 24 spokes in the rear.

Tires

These ended up being lighter and cheaper than Pro4 SC’s, because I guess they’re clearing them out for the new Michelin Power line. I could have gotten the Pro4 Comp limited for even lower weight, but those have no flat protection. Pro4 Comps have the same flat protection and tread as Pro4 SCs, making them a fairly practical tire. They just have a suppler, lighter casing, which also seems a little narrower, as the tires measure closer to 22mm, where many other Michelin tires run wide. Despite Bibendum being white, these tires are just plain black. I like Michelin because they actually make tires for everything, like Continental does, except unlike Continental, Michelin makes slicks without the silly tread pattern that does nothing.

I’m not going to get into the history of tires, because Michelin is one of the oldest tire companies, almost as old as the pneumatic tire. However, it’s worth noting, over a century ago, Michelin got into the tire business because a cyclist rolled up to their shop with a flat, and because of their difficulty with the glued on tubular, invented the first removable tire that wasn’t glued on which had a separate inner tube for ease of fixing flats and replacement. My Michelin tires are also not glued on and have inner tubes for the same reasons. The difference is back then clincher rims actually clinched the tire bead.

Tubes

Skewers

I recommend against these skewers on this blog because of the cost and poor quality, but I still ended up using them because I have them and they are very light. They work, I just wouldn’t buy them again.

Air

(Updated 6-26-16)

No picture (For somewhat obvious reasons)

Can’t forget air. Riding on flat tires is no fun. About 12 grams worth.

Contact Points

Seatpost

Thomson is pretty much synonymous with the 2 bolt design nowadays, but back in the 50’s when Campagnolo made seatposts, and full Campy groupset meant a seatpost too. It gave infinite angle adjustability and secure clamping, especially compared to older designs with separate posts and clamps (although some of these had non-notched designs), which really helped with the finicky set-up of Brooks leather saddles. However, it’s also exceedingly annoying to adjust, trying to fit a small wrench in between the saddle rails, and turning those bolts 1/12 of a turn at a time.

There were a number of knock-offs, and some designs that moved the bolt heads under the seat, making them more accessible, but also adding more setback. And a shift away from Brooks saddle as standard equipment demanded seat posts with less setback. Eventually production shifted towards the much sleeker and simpler (looks aero, lighter, cheaper) single bolt designs.

About 20 years later, in the 70’s, Weyless started making a 2-bolt design with the bolt heads accessible from the bottom and one of the bolts in front of the seatpost. In many way it is very reminiscent of the Thomson design, but while the seat cradle was on the centerline of the seatpost, it wasn’t actually designed to be a zero-offset post. The front half of the rail clamps were removed to give it some setback.

Again about 20 years later, in the 90’s, when all the small CNC boutique shops are in full swing, Thomson decides to make a seatpost. Unlike a lot of these other small CNC shops though, Thomson is an actual machine shop. The bulk to their work is machining parts for the aerospace industry, meaning their CNC work is top notch. Unlike the Weyless, the Thomson is a single-piece design, not a separate clamp attached to a separate post. Thomson seatposts actually start off as an aluminum extrusion, not your typical billet like in most CNC parts, which is extruded with the ovalized hole to optimize strength to weight and the ear lugs running the entire length. The excess material is removed and it is turned down to size, leaving a properly sized post, and the lugs only on the top of the post. As I said with the cranks, gun drilled is hard, doing it with an oval hole would be even harder, which is why even with all their CNC machines, Thomson extrudes the aluminum with the ovalized hole. The post here is an elite, but the masterpiece is further machined to reduce weight. You might think this means they put it in a CNC machine and lighten it some more. Not so. Thomson has a custom tool (which was surely CNC’d) that gradually enlarges the hole. It starts off with a rod the size of the extruded hole, which is used to guide an oval cutter that is just a little bigger, and shaves off just a little bit of material, which is followed by another cutter that shaves off just a little more, and so on and so on. No gun drilling here.

And in accordance with the long tradition of knock-off seatposts, I’m using the 165g GUB seatpost with a 31g plastic shim, even though I have a Thomson post sized for this frame, because the GUB saves me a few grams and being skinnier, along with the plastic shim, would probably be a little comfier. Although if I swapped out the hardware, the Thomson might very well be the same weight. You thought I was going to use the Thomson?

(Updated 6-27-16)

The GUB GS seatpost has been replaced with the lighter (and cheaper) GUB SI seatpost.

You see this kind of seatpost with the cross-pin made by numerous manufacturers, from the poorly made RockBros to some of the lightest and most expensive boutique seatposts on the market. It’s not as nice as a Thomson style seatpost, and the clamp is far less kind to and offers less support for saddle rail with its small contact area. The clamp loads the rails like it is bending a beam, rather than sandwiching them. It is full of holes to allow water into the frame.

Although not as nice and in many ways, inferior, it does what it needs to do, and since my saddle rails are steel, the clamp design, although more finicky, are not a problem. The hole in the cradle is covered with some tape. At 146g, it saves me an additional 19g.

Saddle

It resembles a Selle San Marco Aspide, but with steel rails it still manages a low weight of only 180g. It’s lighter than the classic titanium railed weight weenie saddle, the Selle Italia Flite, and it’s just about as light as the titanium railed Selle Italia SLR listed at 185g (the hollow railed version is lighter, but also has a 30% carbon base).

Stem

(Updated 6-23-16)

Kalloy is one of the major OEM suppliers of components like stems, seatposts and bars. As their name implies, most of their parts are alloy. You can find them rebranded under a lot of different brands, and Kalloy parts are extremely common on stock bikes. Fit and finish are good, they meet CEN standards, and they’re affordable. It’s no wonder they supply so many manufactures with their parts.

UNO is their own house brand, since Kalloy parts run the entire spectrum from the very low end, UNO denotes that it’s a mid to high end product. The ASA-105 made from 7050 aluminum is their premium light weight stem. Even so, it only runs about $20 when UNO branded, and comes in at a super light 107g for a 100mm with the included steel bolts. You could spend a lot more on a name brand stem, and it might not be as light, or it might be the same thing made by Kalloy anyways. Comes in a wide variety of lengths 80-130mm, in both 7° and 17° versions.

Modified with Ti bolts from the Hylix Stem it drops 10g, bringing it down to 97g, only 2g less than the Hylix before, but a whole lot nicer.

This is a Hylix 100mm stem with Ti bolts. It’s junk, it’s poorly made, poorly machined, the clamp overbored, the bottom face is not flat. It will be replaced with a UNO stem sooner or later when I decide on stem length, which should end up being pretty much the same weight after installing Ti bolts.

Spacers

The picture says 18g for 10, right now I have 6 because I haven’t commit to a bar height yet so 11g. These FSA Polycarbonate spacers made from plastic, and are basically as light as a non-ribbed carbon spacer, which is fine because they just deal with compression loads. They’re mostly likely going to end up removed anyways.

(Updated 6-27-16)

Gone! A savings of 11g.

Handlebars

Oval brand, but actually round, just like their wheels. Fairly light weight, but not the lightest. I prefer a 38cm bar and many of the lighter bars only come in 40cm. I actually prefer a 38cm flared bars like FSA, but my 38cm FSA Wing Pro, their lightest alloy model comes in at 285g, although I can imagine the gloss white paint adds some weight.

Bar Tape

Generic handlebar tape. I ended up using ones that were 27g. I may order a few more rolls to see if I can get some more 10g ones. The left over scraps were 4g, bringing it down to 23g and some electrical tape. It doesn’t have any adhesive backing, so I put a very loose wrap of double sided cellophane tape on the bars to prevent creep.

Bar Plugs

A few cents worth of plastic tube plugs, and a little trimming with a knife gets me these 4g bar end plugs, on par with the Schmolkes, and other fancy carbon plugs, to replace the 7g silver plugs (it’s technically not chrome, it’s a coating of aluminum that has been sprayed on in liquid form) that come with the generic tape with something matte black.

Pedals

These are some old Forte SPD compatible road pedals, no longer sold, they’re basically the same as a Wellgo MG-8 with a titanium spindle (the pedals pictured are actually MG-8 bodies) weighing in at 199g. Unfortunately, they use plastic bushing which wear out eventually, which is why the pedal bodies were swapped out.

Technically, these are one of the lighter non-carbon pedal systems. SPD cleats only weigh around 50g, compared to 68g for KEOs or 118g for 3-bolt sp**dplay. On a 2/3-bolt shoe, these pedals are only 250g vs sp**dplay titanium 282g. Still lighter cleats don’t actually reduce the bike weight any. Some day I’ll put non-SPD pedals on this bike. Some day.

*pedal spindles have been sharpie’d because ti nitride doesn’t match anything, it’s fine because nothing should touch the spindle and if it does, it’s going to wear through paint or the coating anyways

Accessories

Bottle Cages

I was originally going to use Tacx Foxys, advertised at 22g, but that turned out to be a complete fabrication, and they didn’t fit the frame anyways. I was considering the Blackburn Slick which are 23g, but an enclosed loop design so they’re more finicky. I settled on these, which were a tiny fraction of the price at $1 and 48g for the pair.

Bolts

What do motorcycles and bicycles share in common? These lightweight alloy M5 bolts of course. They’re used on motorcycles to customize them with various colors. They’re used here for their weight. Four for the bottle cages, and one cut down for the bottom bracket guide.

Chain Catcher

Token chain catcher, because the SRAM one doesn’t work with my braze-on adapter and this is just a little lighter. It comes with an aluminum bolt that would reduce the weight by another gram, but I’m using a titanium bolt for security. The SRAM one got put on the bike that this came off of. It’s not strictly necessary, but it does add some security.

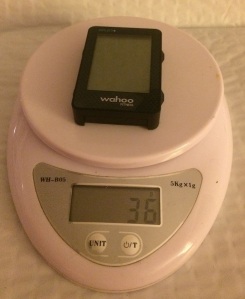

Computer

At only 36g and a screen almost as big as a Garmin 500, the Wahoo RFLKT+ is extremely light for the functionality. It has a customizable display that can display power, HR, cadence, speed, altitude, etc. The only problem, it’s not actually a bike computer. As the name implies, it just RFLKTs the output of your iPhone. Compared to mounting an iPhone on your stem, you can keep it protected from the elements, save battery by turning off the screen, keep it plugged into an external battery, and avoid the uncomfortable glares of fashion conscious roadies (I ziptie those useless Otterbox belt clips no one uses on the stems of some of my other bikes). There’s a little bit of lag too, but not much. It’s not perfect, but I normally carry my phone with my when I ride anyways. The main reason I have the RFLKT+ is because it has an ANT+ bridge, and the old iPhone ANT+ bridge was bulky and for 30-pin iPhones,although it supposedly works with an adapter, leaving you with a very clunky device. It’s needed for the ANT+ power meter. All my other sensors are bluetooth so I didn’t feel like buying a Garmin or a Bryton. They’d weight about the same as the RFLKT+ combined with the speed sensor. I used the stem mount which came in at 11g because it was the lightest.

For the record: When comparing to the UCI minimum weight, computers aren’t included, but computer mounts are, in an effort to curtail racers from chucking their Garmins like they do empty bottles. So it’s not included in the weigh-in.

Speed Sensor

Since the crankset already does cadence, there’s no reason to put a 30g combo sensor on plus a 5g wheel magnet. Not to mention two devices doing cadence might end up with interfere with each other. It’s also nice because it’s hidden completely behind the cassette, and does not require any magnets. In fact, you actually have to remove all magnets from the bike to use it. So how does it work? Not with an accelerometer if that’s what you’re thinking. It works using… magnets? The reason you can’t use it with magnets is because it uses a compass to create a reference. Not that it really matters. The velocomputer is a few grams heavier than the Garmin hub sensor, but also transmits bluetooth.

For the record: When comparing to the UCI minimum weight, this is completely optional, so it’s not included in the weigh-in.

Frame Fittings

Braze-on Adapter

Generic $3 34.9mm adapter, not including the ti bolt, and is still one of the lighter options on the market. Titanium bolt drops it from 20g to 18g. Seems to work just fine.

Seat Clamp

Modified with a slightly longer titanium bolt, I purchased this after the J&L failed on me.

Headset

Nothing to say, it’s a FSA Orbit IS-2 with an alloy crown race that came with the frame, except I split the crown race because that makes it easier to install.

Top Cap

It’s only 1g lighter than the J&L top cap and bolt I have. If I didn’t already have it, it would have been the J&L, both are light have have an aluminum bolt, which is not a problem in practice. The top cap bolt only has to be strong enough to snug up a headset on a threadless headset.

Plug

Technically, I don’t need an expander plug. It’s not even that secure in the aluminum steerer. I could have used an even lighter 5g alloy star nut, but I had this for a carbon fork. The other advantage is it’s removable. I have a 2g cosmetic dust cap for the steerer, that can replace this, the top cap, and the spacers after the stem has been secured for a weight savings of 23g.

Dust cap

(Updated 6-27-16)

The lightest of the light. A custom steerer plug that weights only 2g, that’s less than half the weight of the Schmolke plug and without the 3k weave pattern. It doesn’t support the steerer, it doesn’t let you preload the headset, it doesn’t do anything except cover up the hole left by removing the top cap and expander plug, which are no longer necessary after preloading the headset and tightening the stem. A weight savings of 12g for just a few cents.

Frameset

Frame

The frame is a NOS 2005 Javelin Amarone. Made for only one year, because they cost more to make than carbon frames. The carbon frame that replaced this model actually ended up being heavier. Even though the frame is over a decade old, it still gives frames like the CAADs a run for their money when it comes to weight, weighing in under a kilo at 987g without hanger and cable guide. Those add another 16g. Maybe it’s time for Javelin to bring it back. Being made from Dedacciai U2, it is certainly not heavy metal. Dedacciai called it the third metal, but my periodic table tells me that’s lithium or potassium. I’m pretty sure it’s aluminum, and the other two metals implied are steel and titanium. This short lived generation of sub-kilo aluminum frames has an almost mythical status, very expensive, made only for a short time, exceptionally rare, and quickly displaced by low end Chinese carbon frames. Even the most advanced aluminum frames today like the CAAD12 come in around 100g(?) heavier. Feathery light.

Fork

That brings it to a total of 6565g , over half a pound less than the UCI weight limit, ready to ride including pedals, cages (two of them), power meter, clinchers, actual quick releases, a full 2×11 drivetrain, with a plain chain, a steel cassette, and not a gram of carbon fiber.

Not even adding my (empty) saddlebag, blinky and a bell brings it up to UCI weight.

If you’re interested in upgrading your bike, or getting your feet wet in the weight weenie thing, check out my Bike Upgrade Guide

Some people have said that it is only possible because of the small rare frame. Maybe with some of the self-imposed limitations on consumables and extensive use of cost-conscious parts. For reference a CAAD10 50cm is ~125g less than a 58cm. Factor in ~25-35g for the extra steerer, and maybe 20g for the extra cable. As mentioned earlier a CAAD12 is ~100g more, and would require a strange looking fork crown adapter, but this build starts off over 100g under.

Cut steerer and remove spacers (-25g)

Computer not counted against UCI limit and sensor optional (-55g)

Sp**dplay titanium (-30g)

KCNC Scandium seatpost (-45g)

Red 11-25 cassette (-105g)

Red chain sized for 50×28 (-12g)

Ceramic jockey pulleys (-13g)

AICAN Bungarus or Powercordz (-60g)

Rotor 3D+ No Power (-60g)

Ceramic BB (-10g)

Octaramp chainrings (-20g)

Michelin Pro4 Comp Limited (-30g)

Continetal Supersonic tubes (-25g)

Use a dust cap instead of top/cat expander (-10g)

Stan’s Alpha 340 rims would be stiffer for the same weight.

eeBrakes would offer better braking for a very small weight penalty.

And I could probably manage few more grams doing other tuning and small parts swaps. That’s over a pound of additional potential weight loss. Also if you have more than 1000g of carbon fiber on your bike, it’s a carbon fiber bike, whether or not those grams are in the frameset or elsewhere. I’ve seen many “steel” and “aluminum” bikes with more carbon fiber than my old carbon fiber bike.

Some people have concerns over my component selections. I do in fact have a carbon fork and other wheelsets. No I’m not made out of money, if you couldn’t tell, this was not a money is no object build. Many of the parts I already had on hand. There are lots of cost conscious parts. This blog is a parts listing of budget oriented parts.

Even though I say the brakes and wheels are flexy, I’m not a big guy, they might be a problem, for you.

LikeLike

So how much was the total cost? Would be nice to see it on this article so us fellow readers can judge if it’s cost-effective building a non-carbon bike.

LikeLike

It’s hard to put a price on many of the parts. Power meters are very expensive. Many of the parts were obtained second hand, I already had, or would not buy again. The aluminum fork was obviously not cost effective. Contrary to what most people assume about aluminum and stiffness, it does not make it a boneshaker though. The thing is you’re unlikely to get your hands on a NOS ultralight aluminum frame at any price. New ultralight aluminum framesets come with carbon forks and aren’t cheap, and can exceed the cost of some carbon framesets.

I would say no, it’s not cost effective trying to replicate this build. This is a build of my project bike, not really an example of a budget bike. At the very least, you’re not going to end up using the same frameset. If you’re interested in building up a bike from scratch, I recommend making a spreadsheet, and taking a look at the parts listing for ideas. If you already have a bike and just want to upgrade, I would take a look at the bike upgrade guide on this blog.

I would guess most bikes could lose a pound or two from the upgrades listed there, and over a pound upgrading wheelsets, even if you don’t use a super ultralight wheelset. Being able to build a wheelset helps make light weight wheelsets affordable, although you should be able to find various models of Kinlin rims laced to Bitex hubs at decent prices.

LikeLike

Love the build. I have an 05 Amarone myself but it was built as a budget road bike using primarily used SRAM Force drivetrain. Thank you for all the information you provided.

LikeLike